Jaeckel's Industrial Full Robot Systems

Bringing Robotics & Automation To All Forms Of Business Across America!

Featured Equipment

We utilize advanced technologies, like machine learning and artificial intelligence, to deliver more adaptable systems. They can now adjust to changing requirements, such as different packing patterns or product dimensions, with minimal intervention.

Robot Machine Tending

When your industry requires precision, efficiency, and reliability, Jaeckels Industrial’s robotic machine tending systems can offer the solutions you need. Our systems seamlessly integrate into your existing workflow and redefine the standards of productivity and accuracy that you expect. Whether you’re striving to increase general workplace flow or enhance environmental safety, Jaeckels Industrial takes pride in delivering solutions that work for your unique requirements.

Machine TendingCustom Industrial Automation

Jaeckels Industrial is more than just an industrial automation company that provides a service—it’s a commitment to elevating your operation’s efficiency and precision. We offer solutions that help meet the demands of modern industrial applications by combining cutting-edge technology, meticulous craftsmanship, and a customer-focused approach. Our systems stand the test of time and can improve your bottom line. Whether you need PLC and HMI programming or complete system integration, we’re ready to optimize and future-proof your processes.

Industrial AutomationCustom Industrial Fabricators

Jaeckels Industrial understands that your operations need precision and durability when it comes to fabrication. We bring decades of experience to the field with our family-run business and pride ourselves on delivering industrial fabricators that exceed your expectations. When you choose Jaeckels, you’re investing in craftsmanship that stands the test of time, tailored to withstand the rigorous demands of industrial applications.

Industrial Fabricators

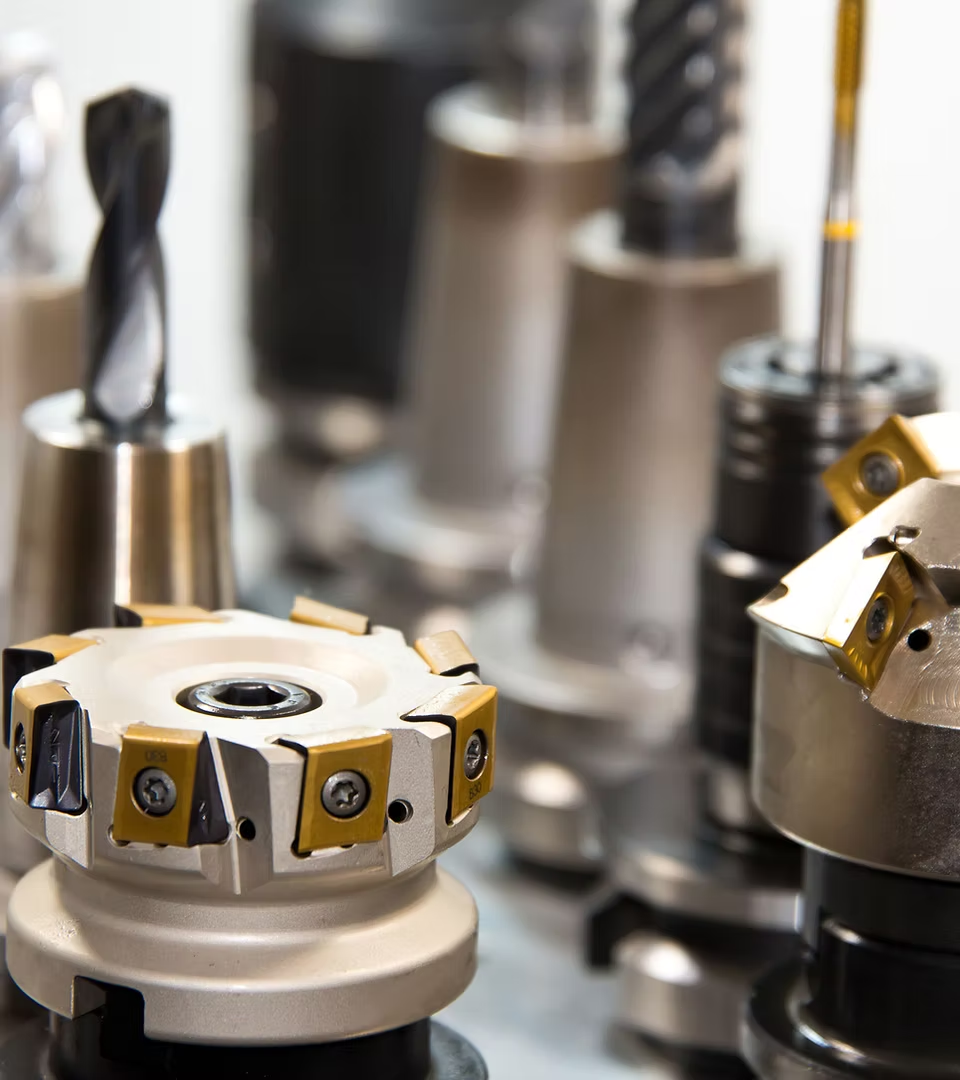

Custom Machining

Full service custom machine shop with CNC Mill, Lathe, Automated Bandsaw, Brake, Shear, and Custom CAD Designs for all of your fabrication needs! At Jaeckels Industrial, we offer industry-leading custom machining services designed to support manufacturers, fabricators, and industrial operations across Minnesota and the Midwest. As a family-run automation and fabrication company, we take pride in delivering precision machining solutions built to withstand the toughest industrial environments — equipment we stand behind with our name and reputation.

Contact UsWhat We Do

We utilize advanced technologies, like machine learning and artificial intelligence, to deliver more adaptable systems. They can now adjust to changing requirements, such as different packing patterns or product dimensions, with minimal intervention. Investing in robotic palletizing systems leads to long-term savings, reduced downtime, and an agile production flow.

Robotics

Robot Programing, Custom Robot Tooling, Robot Integration, Robot Greasing, Preventative Maintenance.

RoboticsAbout Us

Jaeckels Industrial has a mission to bring robotics and automation to all forms of business across America! We are ready to integrate today’s technology in robotics and automation to companies that never thought it was possible or affordable. Specializing in repurposing used robotics, we handle automated systems from the initial design process, to the installation. A simple conveyor or a complex robotic system- we are ready for the task!By automating repetitive tasks, businesses can reduce errors caused by human fatigue and boost overall productivity. The versatility of robotic palletizing systems allows them to handle a wide variety of products with precision, from fragile items to bulky goods.

These systems enhance workplace safety by minimizing reliance on manual labor, requiring less lifting and stacking of heavy objects. Companies can allocate their workforce to more critical and creative tasks, further optimizing operations. We utilize advanced technologies, like machine learning and artificial intelligence, to deliver more adaptable systems. They can now adjust to changing requirements, such as different packing patterns or product dimensions, with minimal intervention. Investing in robotic palletizing systems leads to long-term savings, reduced downtime, and an agile production flow. The ability to meet growing demands efficiently makes adopting these systems a smart, future-forward move for businesses across sectors.