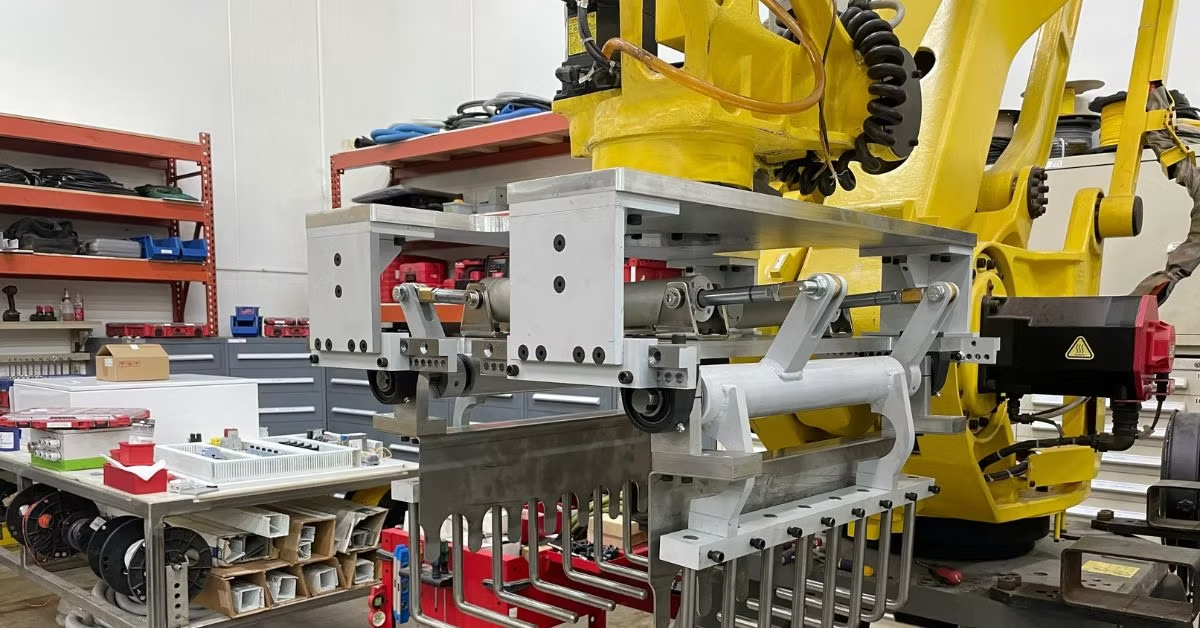

Industrial robots transform manufacturing operations. You know this. But, like all sophisticated machinery, it won’t run forever, certainly not if you neglect it. Robots require systematic care in order to deliver optimal performance, minimize downtime, and extend their operational lifespan. In fact, the difference between a robot that runs for decades and one that fails prematurely often comes down to how well you maintain it.

When you think maintenance, you might think dusting and lubrication. Though those are certainly important tasks, good upkeep entails more. It encompasses preventive measures, predictive analytics, and strategic component replacement as well.

Here, we provide the lowdown on how to keep your industrial robots in prime condition. By adopting these practices, you can boost production efficiency, product quality, and workplace safety.

Essential Daily Maintenance Tasks

Daily maintenance is the most important and easiest part of a robot care program. These routine checks take very little time and compensate you generously by preventing major preventable issues from developing.

Visual Inspection Protocol

Start each shift with a comprehensive visual inspection of your robotic systems. Look for obvious signs of wear, damage, or contamination on external surfaces. Check for loose bolts, frayed cables, unusual accumulation of debris around joints and moving parts, and other such issues. If it looks off, inspect it further.

Pay particular attention to the robot’s teach pendant and control cabinet. These components house sensitive electronics that can fail if contaminated with dust, moisture, or chemicals. Any visible damage to protective covers or seals should be addressed immediately.

Operational Parameter Monitoring

Monitor key performance indicators during normal operation. Listen for unusual sounds such as grinding, clicking, or excessive motor noise. These audio cues often provide early warning of mechanical problems before they cause catastrophic failure.

Check that all programmed movements execute smoothly without jerking or hesitation. Erratic motion patterns frequently indicate issues with servo motors, encoders, or mechanical components that require immediate attention.

Weekly Maintenance Requirements

Weekly maintenance activities build upon daily inspections to address components that don’t require constant attention but need regular monitoring.

Lubrication System Management

Most industrial robots use automatic lubrication systems that require periodic monitoring and refilling. Check lubricant levels in all reservoirs and top off as needed using manufacturer-specified lubricants only.

Using incorrect lubricants can damage seals, contaminate internal components, and void warranty coverage. Always verify part numbers and specifications before adding any fluids to your robotic systems.

Cable and Harness Inspection

Robot cables endure constant flexing and can develop internal breaks that aren’t immediately visible. That’s why you should inspect all power and signal cables for signs of wear, kinking, or damage to outer jackets. Pay special attention to areas where cables enter and exit the robot housing.

Test cable continuity using appropriate diagnostic equipment when visual inspection reveals potential issues. Replace damaged cables immediately rather than waiting for complete failure, which could be catastrophic for your operations.