Many industries rely on automated systems that use preprogrammed software to control machines and guide them into performing the proper actions. The two major programming options for these systems are programmable logic controllers (PLCs) and human machine interfaces (HMIs). Despite both being beneficial options for running automated systems, they serve distinct purposes and work in unique ways.

Companies looking to invest in automated systems should know what the difference is between PLC and HMI programming. Understanding their differences helps business owners make informed decisions about implementing automation that can transform their operations for the better.

Understanding PLC Programming Fundamentals

PLC programming creates the general command structure and processes of an automated system. These controllers execute programs that determine how equipment responds to various inputs, making split-second decisions that keep production lines running smoothly.

The programming focuses on creating logical sequences that translate real-world conditions into automated actions. These programs use sensors that pick up on temperatures, pressure levels, or positions to determine an appropriate response. For example, when a sensor indicates the temperature is too high, it may automatically open a valve to activate the cooling system.

Small companies benefit from PLC programming because it eliminates the need for complex hardwired control panels. Operators can easily modify software programs to accommodate new equipment or adjust existing operations instead of rewiring circuits.

Core Functions of HMI Programming

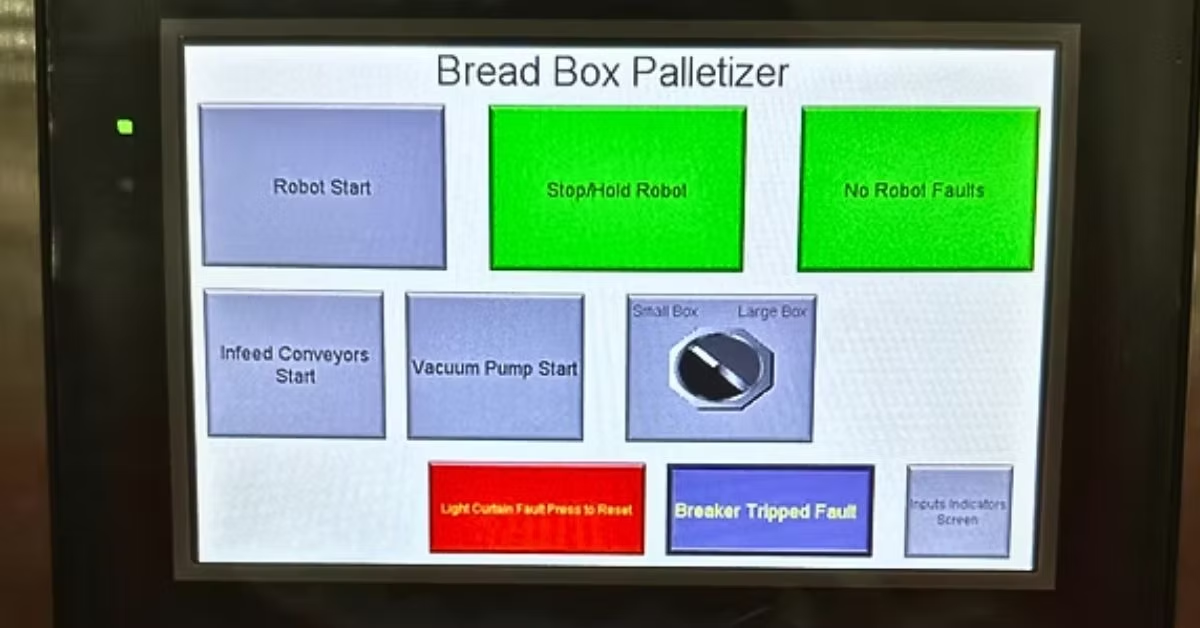

HMI programming bridges the gap between complex automation systems and human operators. These interfaces display critical information in formats that operators can quickly understand and act upon, transforming raw data from PLCs into meaningful visual representations.

This type of programming involves designing screens that display the process status, equipment conditions, and operational parameters with graphics, charts, and control buttons. Operators can use this information to start and stop equipment, change the setpoints, acknowledge any alarms, and monitor production metrics without needing to know the more detailed technical aspects of the underlying control systems.

Effective HMI programming prioritizes clarity and ease of use to help operators quickly identify problems, make necessary adjustments, and maintain optimal system performance throughout their shifts.

Programming Languages and Approaches

PLC programming involves specific language to operate industrial control applications. They use ladder logic, which focuses on symbolic representations to resemble electrical circuits. This visual programming method allows technicians with electrical backgrounds to understand and modify control programs relatively easily.

Function block diagrams and structured text represent additional programming options for more complex control algorithms. These approaches suit applications requiring advanced mathematical calculations or sophisticated process control strategies that extend beyond basic on-off logic.

HMI programming uses tools and languages that focus on a more straightforward, user-friendly interface. Many HMI development platforms provide drag-and-drop functionality that simplifies screen creation, allowing programmers to build comprehensive operator interfaces without extensive coding experience.

Hardware Requirements and Specifications

When looking at the differences between PLC and HMI programming, it’s important to consider the hardware limitations of your equipment. PLCs feature multiple input and output modules that connect directly to field devices such as sensors, motors, and actuators. All hardware should be able to handle electrical noise, fluctuating temperatures, and vibrations while maintaining reliable operations.

Processing power varies significantly based on application complexity. Simple on-off control applications require basic PLCs with limited memory and processing capabilities, while advanced process control or motion applications demand high-performance controllers with extensive memory and specialized modules.

HMI hardware ranges from simple text displays to sophisticated touchscreen panels with advanced graphics capabilities. An important part of this decision often depends on the number of operators working on the system and the level of necessary interaction for effective control.

System Integration and Communication

Modern automation systems rely on seamless communication between PLCs and HMIs through industrial networking protocols. These communication links allow HMIs to read data from PLCs and send commands back to the control system, creating unified automation solutions.

Most protocols use a standard Ethernet-based communication to provide fast, reliable exchanges between system components. These options allow for real-time information that reflects actual system conditions with commands reaching appropriate control functions without confusing delays.

Proper integration requires careful planning of communication networks, data mapping, and security measures to prevent unauthorized access to critical control functions. Small companies must consider these factors when designing automation systems that will grow with their operations.

Development Time and Complexity

PLC programming typically requires more time during initial development phases because programmers must account for every possible operating condition and safety scenario. The logic must handle normal operations, startup and shutdown sequences, alarm conditions, and emergency stops while maintaining safe operation under all circumstances.

HMI development focuses more on user experience design and information presentation. While the programming is complex from a logical standpoint, it requires establishing effective operator interfaces to understand the workflows, alarm priorities, and information to support efficient decision-making.

Both programming scales come with different levels of complexity. Simple applications may require only basic programming skills, while more difficult manufacturing operations demand extensive expertise and training in both control logic and interface design.

Maintenance and Troubleshooting Differences

PLC maintenance involves monitoring system performance, updating control logic as processes change, and diagnosing hardware failures. Technicians must understand both the programming logic and the physical systems being controlled to effectively troubleshoot problems and implement improvements.

HMI maintenance focuses primarily on software updates, screen modifications, and user account management. You can troubleshoot these systems by looking for communication issues, updating graphics or displays, and making sure the operator interfaces accurately reflect the current system conditions.

It’s a good idea to engage in regular backup procedures for both models to prevent data loss. However, backup strategies may differ based on the type of information you’re preserving and system availability.

Choosing the Right Programming Approach

Small companies must evaluate their specific operational needs to determine the appropriate balance between PLC and HMI programming investments. Operations with simple on-off control requirements may benefit from basic PLC programming with minimal HMI functionality, while complex processes require sophisticated programming for both systems.

You can make your decision based on operator skill levels, complexity processes, safety requirements, or current growth plans. If your company is aiming for significant expansion, you may want to invest in more capable systems upfront to avoid additional upgrades down the road.

Jaeckels Industrial has years of experience helping small businesses upgrade to automation, and our expertise in PLC and HMI programming can help streamline your operations and enhance efficiency. Let us tailor an automated solution for you to create measurable results and set up your business for long-term success.